The Process

Quality

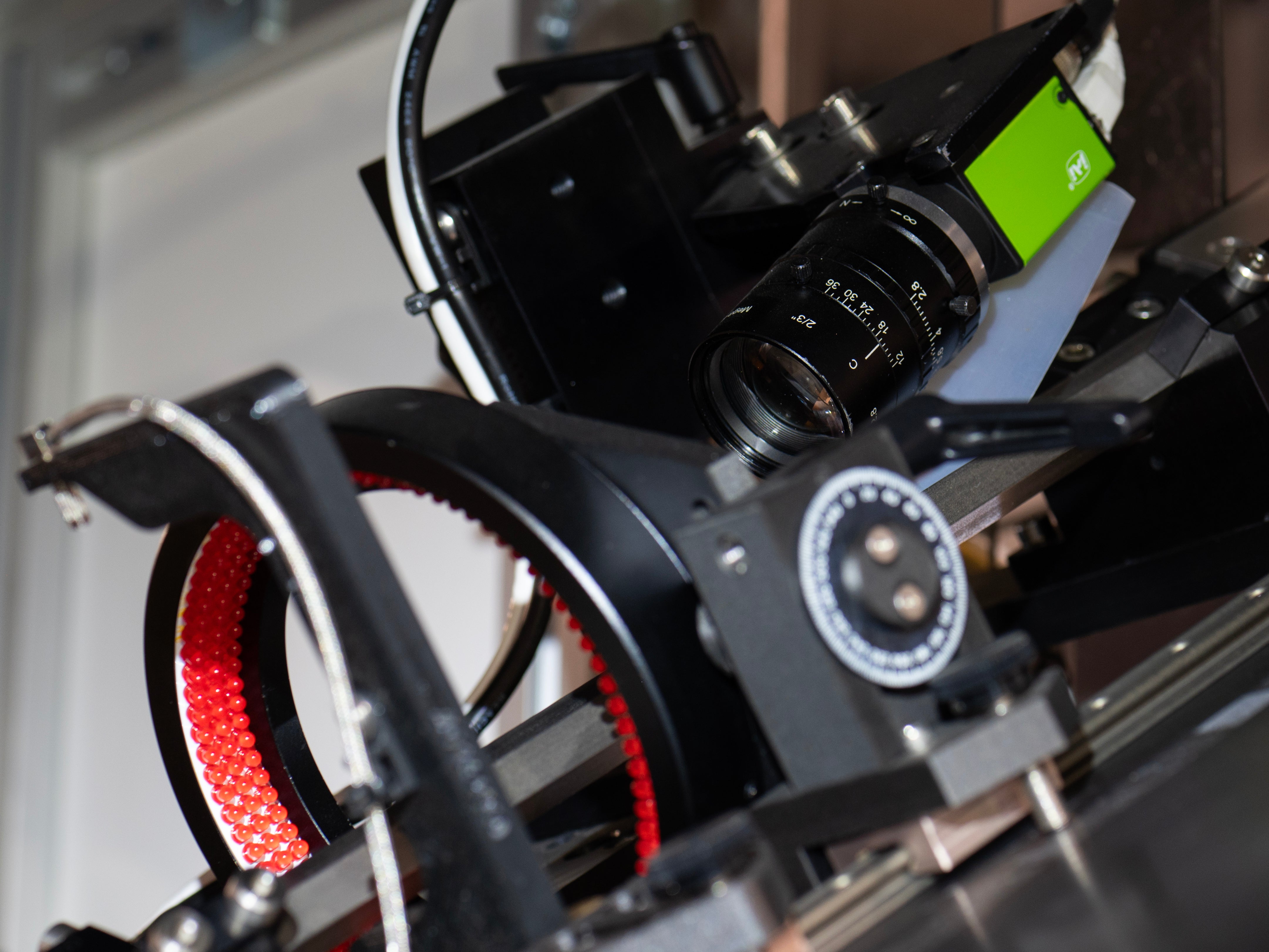

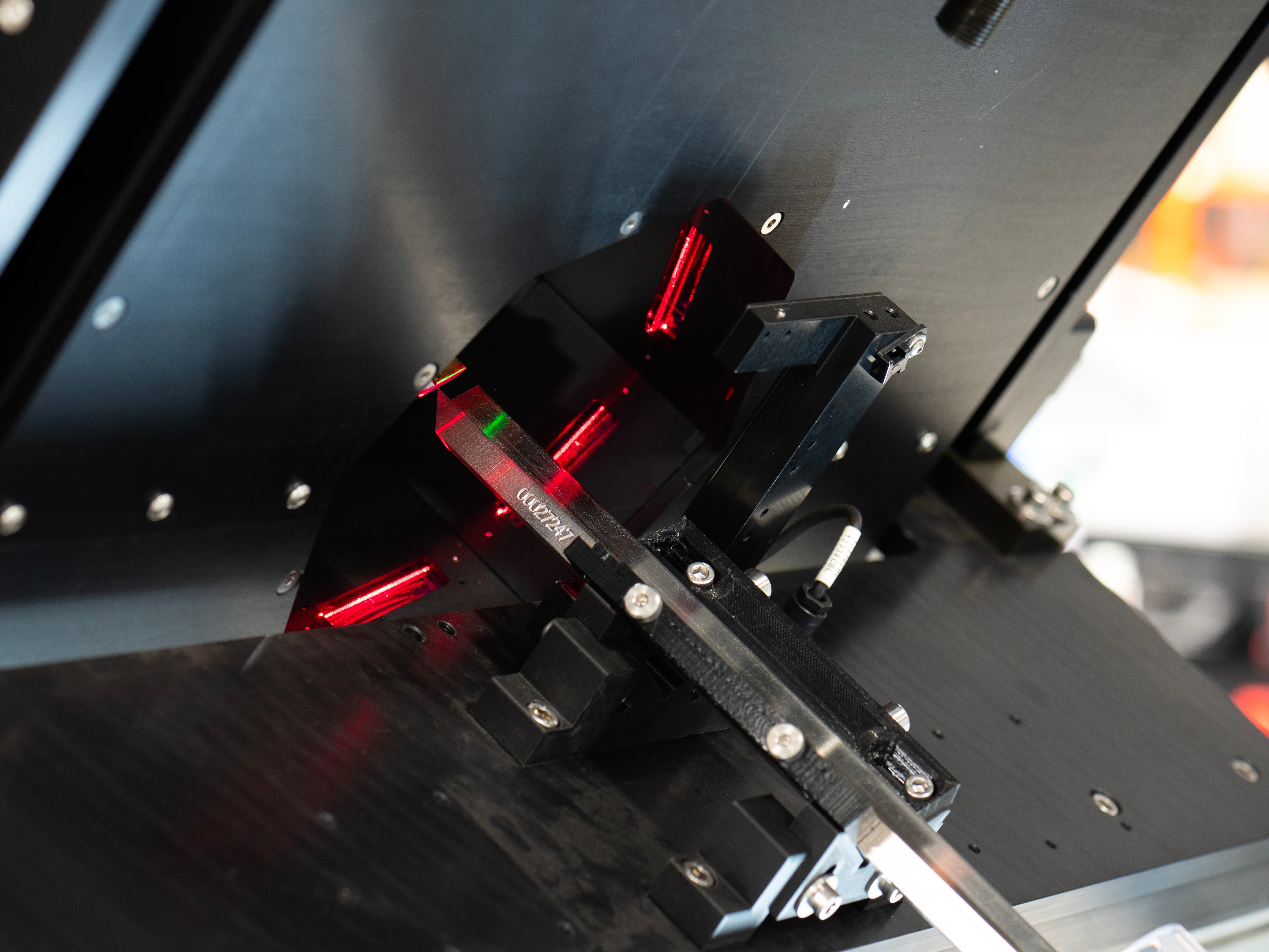

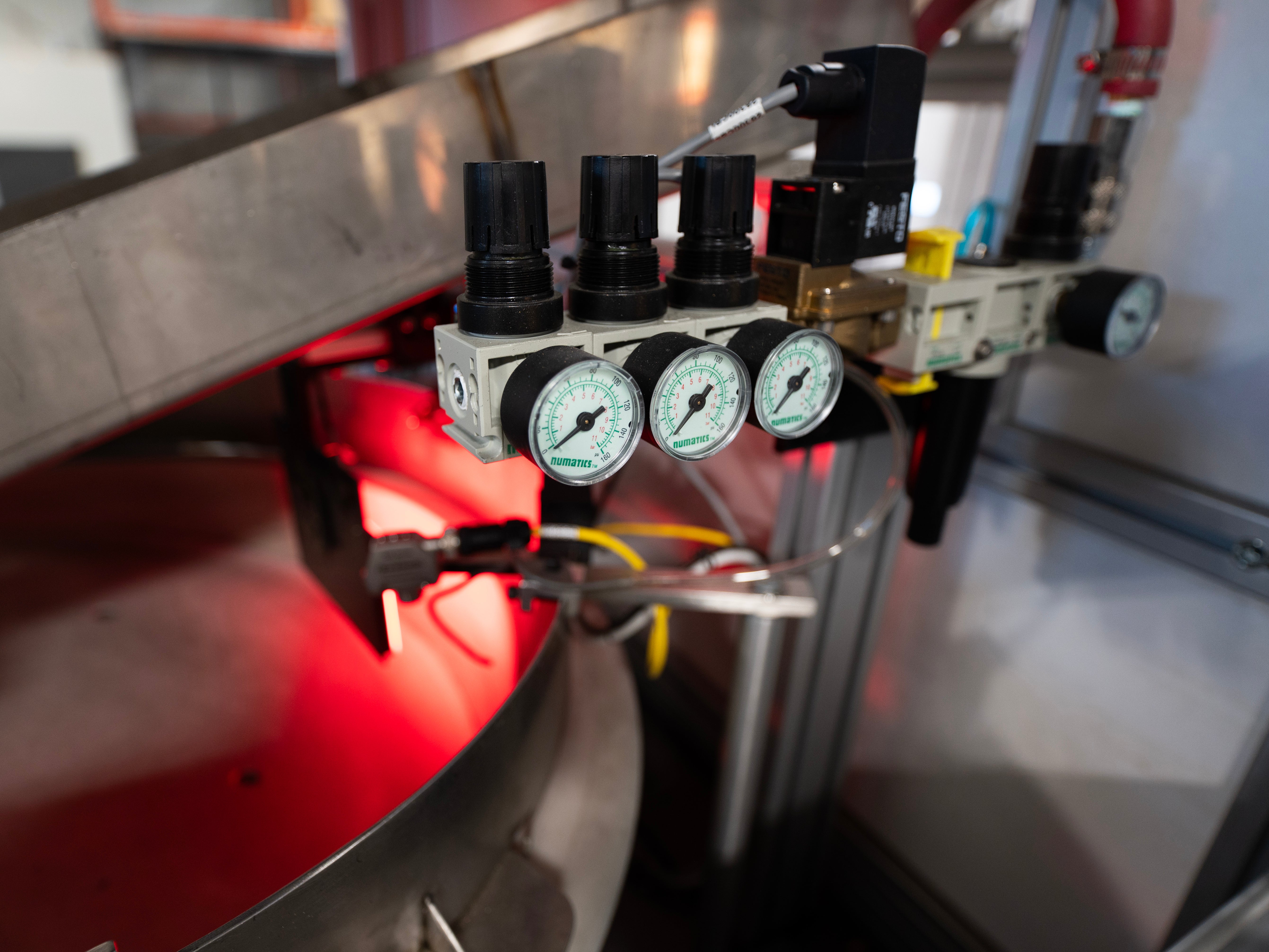

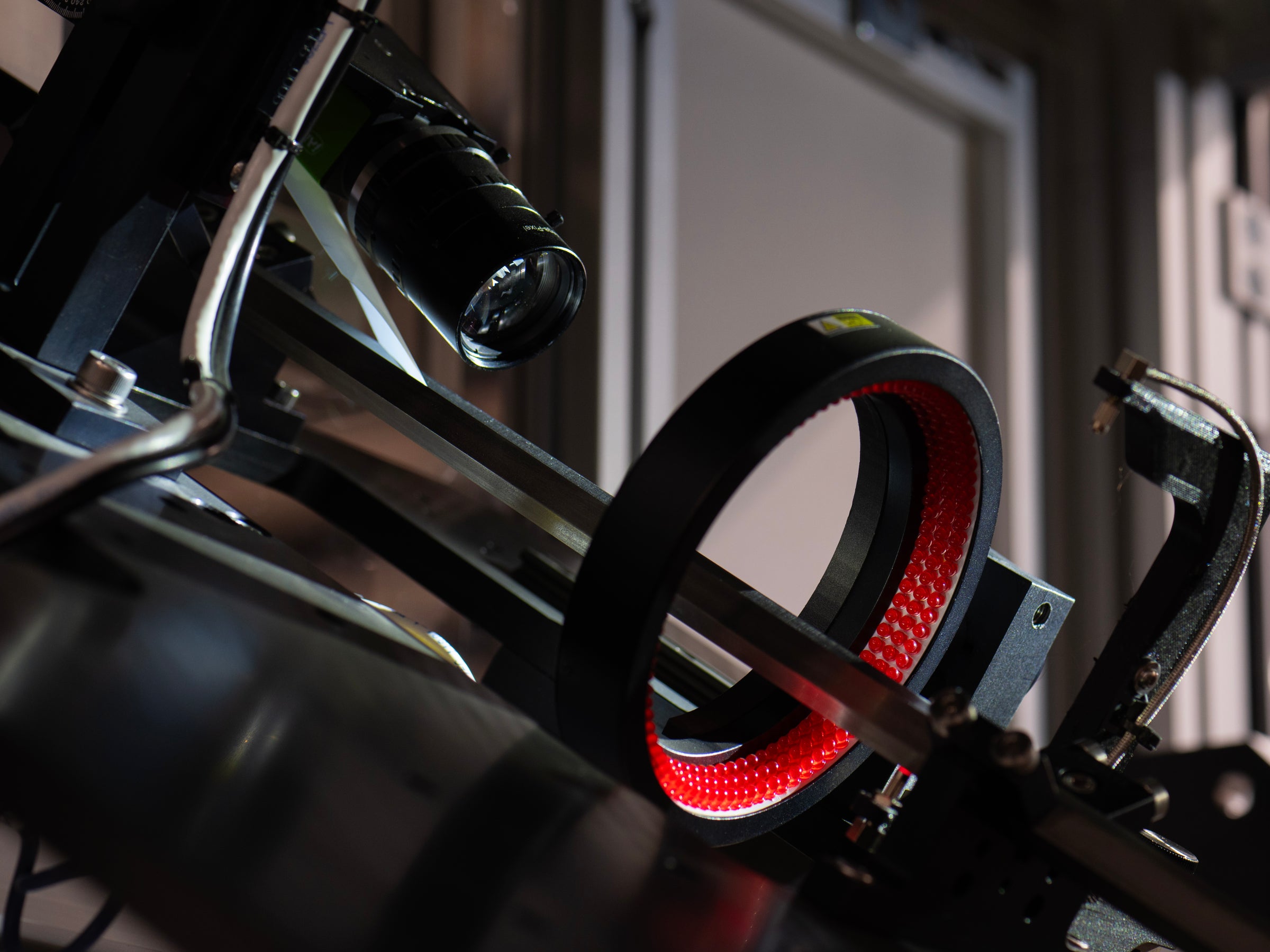

Total Inspection:

9 x CCD Camera Check

5 x Laser Check

4 x 3D Imaging Check

2 x Case Gauge Check

1 x Visual Inspection

Components

All the components will go through the state-of-the-art inspection machine to check all aspects. Checkpoints include shape, length, and diameter. to a point of ±0.005mm (±0.00019”) accuracy. A sample of each component will be selected for composition evaluation. The good parts will be sorted, logged, and stored for future production.

Loading

Each round will go through the following inspection process during the loading: primer check, debris check, two laser powder checks, laser OAL check, and case gauge. Sampling checks of powder charge, OAL, and crimp are consistently applied.

Finished Cartridges

The finished cartridges will be inspected to ensure the final product comply with the SAAMI standard. The Inspection machine will examine additional aspects such as concentricity, physical/cosmetic defects, primer orientation/depth, and the headstamp of each finished cartridge.A final visual inspection will be performed during the packaging process. Finished cartridges will be sampling selected and test fired on our ballistic testing equipment to ensure the proper pressure and velocity.